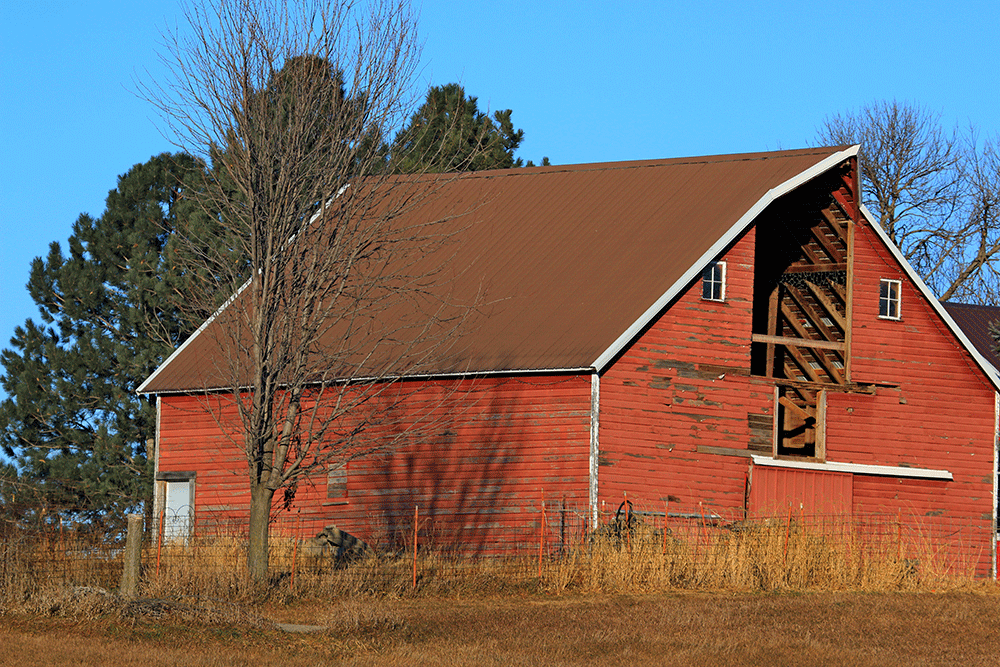

Pole Barn, your time is up.

Back in the day, pole barns were a welcome invention, as farmers and ranchers enjoyed the onset of large mechanical equipment over their ancient manual techniques. But it was all coming to pass during the Great Depression, and farmers looked for economical solutions to house the newfound large equipment, which was concurrently becoming available through agricultural innovations.

Albeit cheap and practical for the times, the wooden-structurally-supported buildings didn’t weather well and still don’t. The amount of wood needed to supply the required support for strong wind and heavy snow was not yet factored into the equation. The buildings lost integrity over a shorter period of time than was expected.

Wood structural support was also exposed to the consequences of pests and decay. It doesn’t take much for moisture to begin breaking down the organic material. Not to mention being highly combustible, fuel stored indoors was undoubtedly dangerous.

But moreover, is the consequence of having wooden poles occupying soils which, by nature, move. Expansion and contraction of soils per weather dictates make it pretty much a given that the support the building is relying on, will move. Especially in areas where the soils are highly expansive clay-based, expect the wooden poles to move; and your barn to move along with it.

While pole barns offer more flexibility in finishes, such as greater ease of window and walk door placement, drywall addition to 2 x 4’s, less expensive foundation worth, the cost of upkeep and maintenance required over time most likely surpasses the upfront cost of going with virtually maintenance-free solid I-beam steel construction.

Durability is a key characteristic of steel buildings, as it doesn’t warp, crack or rot easily. Galvanization methods-not to mention the very popular Galvalume metal sheeting products-create a zinc finish which is rust resistant. I-beam steel building mainframes, secondary supports, wall sheeting, and even colored finishes are up-to-date with technologies, and products are warrantied to last for decades.

The strength of steel allows for clear-span design meaning there is no need for interior support columns interrupting the flow of indoor building space. While pole barns are limited to about 90 feet span, steel buildings can span the width of about 300 feet. Loads are transferred from the roof to the walls, rather to the middle. This prevents sagging of barn roofs.

Every I-beam steel building is prefabricated in the factory to meet design codes for snow loads, wind speed loads, and seismic activity specific to the owner’s location. It’s possible to get the perfect design and strength of your steel building barn structure and never have to second guess whether the structure will make it through the storm. Steel supports are anchor-bolted into concrete foundations or piers, as per the drawings and plans supplied to every unique building. There is no worry that the posts will be rotting out of the soil anytime soon.

Design Flexibility for the ease of expanding when life calls for more space is another advantage to steel building structures. Metal buildings are far more simply altered, and added to, than alternative construction forms. Many do-it-yourselfers over the years have appreciated the greater possibilities a steel building structure offers.

“Allow the benefits of the long-run to assist in your decision for steel barns over pole barns today,” suggests John Barber, owner of Factory Steel Overstock. “Our repeat customers are happy to attest to that! Time and labor IS money saved over the virtually maintenance-free, decade-spanning life of steel.”